Key Takeaways

- Multi-agent systems decentralize decision-making in supply chains, improving responsiveness, adaptability, and resilience across diverse and dynamic operational environments.

- MAS enables agents to act independently yet coordinate effectively, transforming fragmented supply chains into collaborative, intelligent networks.

- These systems enable real-time data processing and decision-making, allowing businesses to proactively manage disruptions, shifts in demand, and supply chain variability.

- MAS scales effortlessly, allowing for the seamless integration of new entities, such as suppliers, warehouses, or retail points, without requiring the redesign of existing systems.

- Implementing MAS involves clear goal-setting, role definition, phased deployment, and continuous evaluation to ensure alignment with business needs and technological infrastructure.

According to research, the supply chain sector has evolved into a multifaceted, constantly shifting ecosystem that encompasses multiple participants, including manufacturers, logistics providers, retailers, and distributors. The fact that supply networks are no longer simple cannot be overlooked. Every entity operates according to its specific requirements, encompassing data systems, strategies, and priorities. This is why decision-making and real-time coordination are prevalent challenges. Conventional supply chain management systems frequently struggle to adapt to changing environments and evolving customer needs. Therefore, multi-agent systems are an appropriate approach to address this.

Multi-agent systems comprise innovative agents that interact with one another to fulfill common or individual organizational objectives. These agents showcase several supply chain elements, including customer service modules, inventory systems, transport units, and warehouses. Every single agent can make fast decisions. Apart from this, they can also communicate and negotiate with other agents to make sure companies obtain a desirable outcome. The core benefits of MAS lie in their distributed innovation and autonomy. Rather than relying on a centralized system that may give rise to unwanted challenges, MAS promotes decentralized decision-making. This results in quick response times, enhanced adaptability, and improved resilience. For example, a delivery route does not meet the requirements. In that case, the logistics agent can adjust the route in consultation with the inventory and sales experts to avoid unwanted delays.

Additionally, MAS enables adaptability and customization, allowing firms to tailor the system to their specific needs and requirements. MAS is particularly convenient for companies worldwide and in emerging market situations. Henceforth, implementing MAS may help improve collaboration, efficacy, and exposure across every layer of the supply chain as firms continue to expand their operations.

Also read: Blockchain Integration with AI Agents for Supply Chain Transparency

Understanding Multi-Agent Systems (MAS) in Supply Chains

As global supply chains become increasingly complex, organizations use intelligent technologies to manage and optimize their operations. Among the most promising approaches is Multi-Agent Systems (MAS). MAS comprises multiple intelligent agents—autonomous, decision-making entities interacting within a shared environment. These agents operate independently yet collaboratively, processing localized data to make real-time decisions and collectively pursue overarching goals.

In a supply chain context, each agent can represent a specific entity or function, such as a supplier, manufacturing plant, warehouse, logistics provider, distribution center, or retail outlet. Each agent is designed with its objectives and rules, enabling it to act autonomously while still maintaining communication and coordination with other agents. For instance, a logistics agent might optimize delivery routes, while a warehouse agent focuses on inventory levels. These agents can negotiate and share information to ensure smooth operations across the supply chain.

The hallmark of MAS is its distributed decision-making structure. Unlike centralized systems that depend on a single control point, MAS distribute control across all agents. This decentralization offers several critical advantages in supply chain management. It improves flexibility, enabling quicker responses to changes in demand, supply disruptions, or unexpected constraints. The system becomes inherently more robust and adaptive, qualities especially valuable in today’s volatile and uncertain markets.

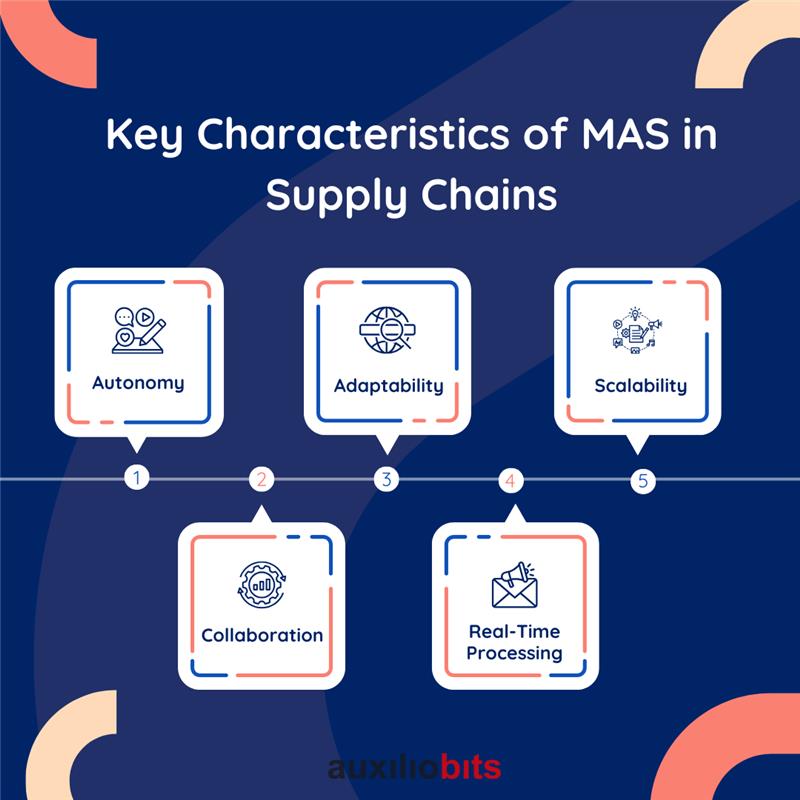

Key Characteristics of MAS in Supply Chains

We have listed the key characteristics of multi-agent systems in the supply chain below. Check them out.

1. Autonomy

Each agent operates independently, using local data and logic to make decisions. This autonomy reduces the need for constant oversight or central command, enabling faster decision-making at each node in the supply chain.

2. Collaboration

Despite their independence, agents actively collaborate by sharing data, negotiating terms, and coordinating plans to achieve their objectives. For example, if a delivery delay is expected, a logistics agent can alert the warehouse and customer service agents, who may adjust stock levels or update delivery commitments.

3. Adaptability

MAS are designed to respond dynamically to changes in their environment. Whether it’s a supplier issue, a surge in customer demand, or a transportation delay, agents can quickly recalibrate their strategies and communicate changes to relevant peers, maintaining operational continuity.

4. Scalability

One of MAS’s strengths is its ability to scale without disrupting the system. New agents—such as additional suppliers, distribution nodes, or retail channels—can be introduced or removed as needed without requiring a redesign of the entire architecture.

5. Real-Time Processing

MAS enables real-time monitoring and decision-making, enhancing responsiveness across the supply chain. Agents continuously process incoming data, identify anomalies or opportunities, and take corrective or optimizing actions without delays.

Multi-agent systems embed intelligence and communication capabilities throughout the supply chain, transforming traditional linear operations into adaptive, self-organizing networks. This results in improved agility, better risk management, and optimized performance. For businesses seeking digital transformation and operational excellence, MAS provides a scalable, resilient, and future-ready foundation

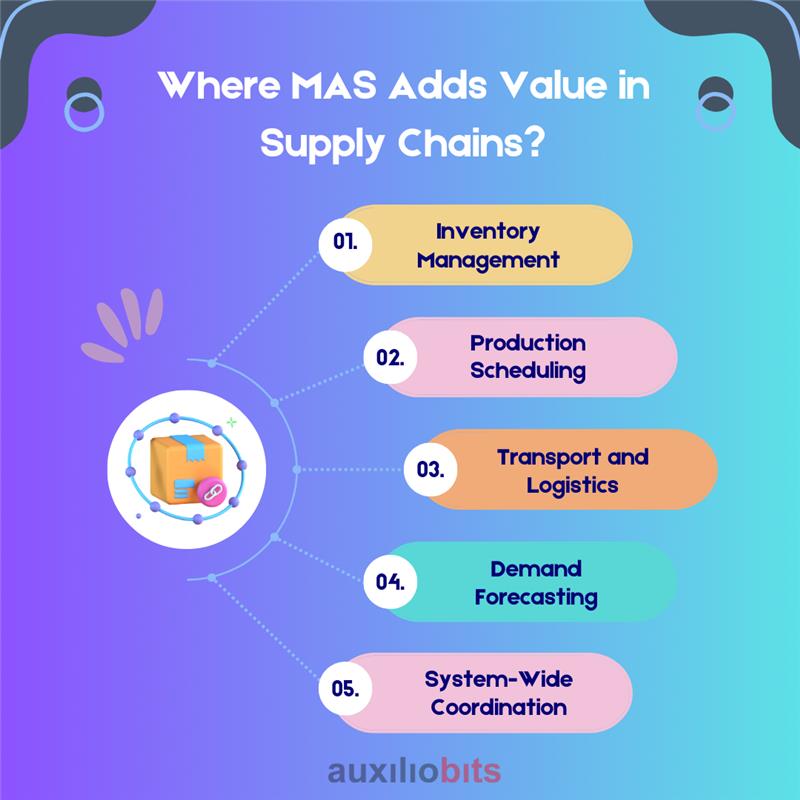

Where MAS Adds Value in Supply Chains?

Implementing Multi-Agent Systems (MAS) within supply chains revolutionizes how various components operate and interact. By embedding intelligence into discrete supply chain elements, MAS ensures real-time responsiveness, predictive planning, and synchronized execution across all levels of the supply chain. Below are key areas where MAS adds significant value:

1. Inventory Management

MAS introduces intelligent inventory agents that continuously monitor stock levels, usage patterns, and replenishment cycles to optimize inventory management. These agents can autonomously evaluate when stock falls below threshold levels and proactively trigger restocking orders. By collaborating with suppliers and logistics agents, they ensure timely replenishment without overstocking, reducing both holding costs and the risk of stockouts. Additionally, inventory agents can adapt based on seasonal demand trends or sales patterns, making inventory management more dynamic and precise.

2. Production Scheduling

In manufacturing environments, factory agents play a vital role in optimizing production workflows. These agents manage machine utilization, labor allocation, material availability, and production timelines to maximize efficiency. By communicating with demand forecasting and inventory agents, production schedules can be adjusted to align with current demand and stock levels, ensuring optimal utilization of resources. This results in reduced lead times, minimized waste, and improved resource efficiency. Factory agents can respond quickly to disruptions such as equipment failures or urgent orders, reallocating tasks to maintain continuity.

3. Transport and Logistics

Logistics agents handle the complexity of shipping and transportation by assessing real-time traffic data, vehicle availability, and delivery deadlines. These agents optimize routing, schedule pickups, and coordinate loading with warehouse agents to streamline dispatch processes. In the event of delays, they dynamically reroute shipments and notify other relevant agents, such as customer service or inventory, ensuring transparency and minimizing operational friction. This level of coordination enhances delivery accuracy and lowers transportation costs.

4. Demand Forecasting

Retail or point-of-sale (POS) agents gather and analyze customer purchasing behavior, seasonal trends, and the impact of promotions on sales. These insights are shared upstream with production and inventory agents, enabling more accurate demand forecasting. This reduces the bullwhip effect, where small fluctuations in demand cause more considerable distortions up the supply chain, and helps align production and inventory with real-time market needs.

5. System-Wide Coordination

The true strength of MAS lies in holistic coordination. Each agent focuses on its specific role and communicates constantly with others to ensure the entire supply chain operates smoothly. They share updates, negotiate constraints, and collectively resolve issues, resulting in increased agility, reduced response times, and improved overall system performance. This interconnected intelligence transforms supply chains into adaptive, collaborative networks that can thrive in complex environments.

Implementation Framework for Multi-Agent Systems in Supply Chains

Implementing a Multi-Agent System (MAS) in a supply chain environment requires a structured approach to ensure effectiveness, alignment with business goals, and seamless integration with existing operations. Below is a step-by-step framework that organizations can follow to deploy MAS in their supply chains successfully:

Step 1: Define Use Cases and Goals

The implementation journey begins with a clear understanding of the specific supply chain challenges or inefficiencies you intend to address. These could include delayed deliveries, excess inventory, poor demand forecasting, or coordination issues within departments. Set well-defined goals such as improving responsiveness, reducing operational costs, increasing service levels, or mitigating supply chain risks. This step helps narrow the scope and align the MAS implementation with measurable business outcomes.

Step 2: Design Roles and Responsibilities

Once the goals are established, design agents that mimic the functions of existing supply chain elements should be created. Each agent should have a specific role, such as procurement agent, inventory agent, production agent, logistics agent, or retail agent, with clear responsibilities and decision-making boundaries. Defining these roles early ensures that agents operate effectively and do not overlap or interfere with one another, allowing for smoother collaboration and decentralized control.

Step 3: Establish Communication Protocols

For a MAS to function cohesively, agents must communicate effectively with one another. This involves developing standardized communication protocols, including data formats, message structures, and communication channels, to ensure consistent and effective communication. These protocols facilitate seamless information exchange between agents, enabling real-time collaboration, negotiation, and decision-making. The communication framework should be secure, reliable, and scalable, whether the system uses XML, JSON, or proprietary APIs.

Step 4: Integrate with IT Infrastructure

MAS must be integrated with the organization’s existing IT systems, including ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), WMS (Warehouse Management Systems), and TMS (Transportation Management Systems). This ensures agents have access to real-time data and operational context. Middleware or integration platforms may be necessary to bridge the compatibility gaps between agents and legacy systems, enabling seamless data flow and interaction.

Step 5: Deploy in Phases

Begin with a pilot implementation focused on a specific function, department, or region. This controlled rollout enables close monitoring of performance and the identification of early challenges. Gather feedback, track key performance indicators (KPIs), and iterate on agent behaviors. Once validated, scale the deployment gradually across broader supply chain functions or geographic areas, minimizing risks and ensuring user adoption.

Step 6: Ongoing Evaluation and Refinement

Post-deployment, continuously monitor agent performance using system logs, analytics dashboards, and stakeholder feedback. Evaluate how effectively agents are meeting their objectives and collaborating to achieve their goals. Based on insights, adjust agent algorithms, introduce machine learning capabilities, or fine-tune decision rules. Continuous improvement ensures the MAS remains aligned with evolving business needs and market conditions.

Final Thoughts

Multi-agent systems provide a compelling model for optimizing supply chains. Their ability to decentralize control, adapt to real-time conditions, and collaborate across a network brings new intelligence to supply chains.

MAS offers a strategic path forward for companies ready to evolve beyond rigid hierarchies and manual interventions. When carefully designed and implemented, these systems can redefine supply chain performance and resilience for the digital age.