Key takeways

- A business that manufactures products has a multitude of administrative and non-administrative functions that need to function seamlessly for creating a product and marketing it.

- Technologies like Robotic Process Automation (RPA), Artificial Intelligence (AI), Machine Learning (ML), Natural Language Processing (NLP), the Internet of Things (IoT), 5G, Cloud, etc., are expected to dominate the manufacturing sector.

- In the pre-automation era, administrative and non-administrative processes were slow and prone to human errors. They also required a large workforce to accomplish various tasks.

- Automation optimizes manufacturing functions, reduces time to market, enhances the quality of products, reduces wastage, and boosts productivity.

Manufacturing is the backbone of any economy. In the most basic terms, manufacturing is converting raw materials to finished products. A business that manufactures products has a multitude of administrative and non-administrative functions that need to function seamlessly for creating a product and marketing it.

Technology has always played a vital part in the manufacturing sector. Manufacturing has been one of the first sectors that started using machines. Industrial machinery completely transformed how the manufacturing sector functions. Machines replaced humans in labor-intensive jobs and created superior products at a high speed when the industrial revolution took place.

Then came the computer age wherein the introduction of spreadsheets, Computer-Aided Design (CAD), Computer Aided Machinery (CAM), etc., further enhanced the outcomes in the manufacturing sector.

Fast forward to Industry 4.0!

Industry 4.0 is the age of unprecedented technological disruption. Technologies like Robotic Process Automation (RPA), Artificial Intelligence (AI), Machine Learning (ML), Natural Language Processing (NLP), Internet of Things (IoT), 5G, Cloud, etc., are slowly but surely spreading their wings and are expected to dominate different sectors.

Businesses across the globe have accelerated their digital transformation journeys during the pandemic when they realized its benefits. Automation technologies have become the mainstay of the industry since the COVID-19 pandemic.

The manufacturing sector wholeheartedly welcomed automation for streamlining various processes on the shop floor. Bots started appearing in different areas of the manufacturing units. However, automation has a much higher potential than just automating different manufacturing processes!

Automation technologies can revolutionize both non-administrative and administrative functions! They can power the growth of any enterprise by enhancing productivity.

The manufacturing sector can leverage disruptive technologies to gain a competitive edge in the market.

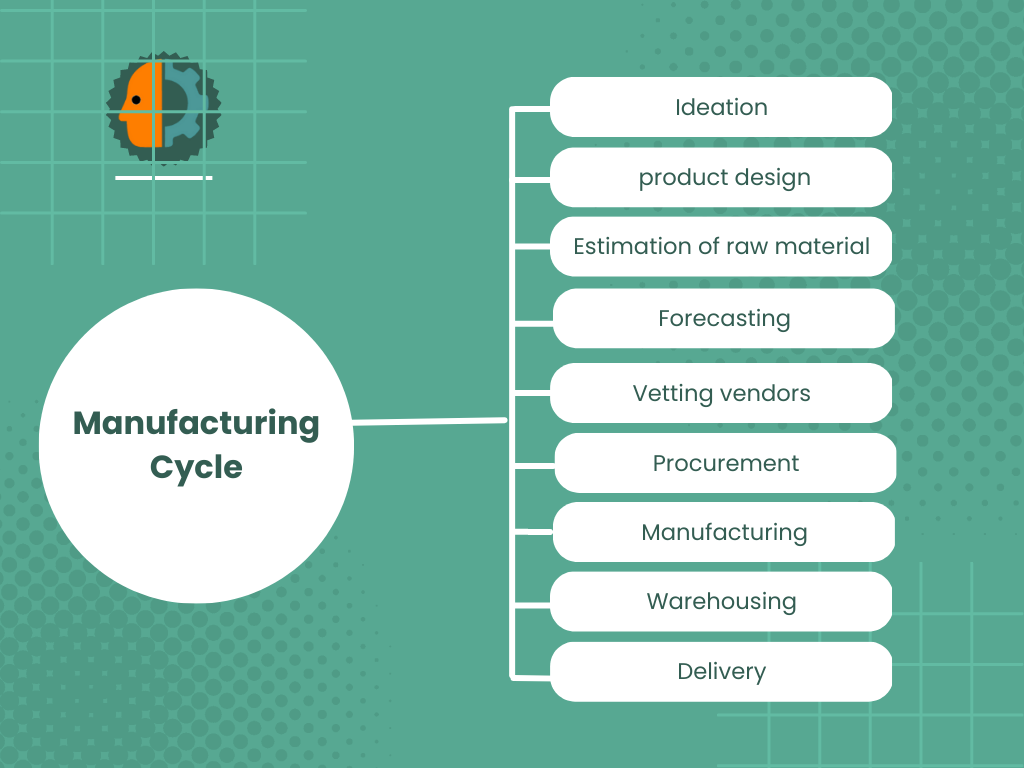

Here’s a brief overview of a manufacturing cycle:

- Ideation

- Development of product design

- Estimation of raw material

- Forecasting

- Vetting vendors

- Procurement with processes like invoice processing, PO generation, and more.

- Manufacturing

- Warehousing

- Delivery

Several other functions support the basic manufacturing cycle so that the business meets its goals.

Some of these functions include:

- Human Resource Management with functions like recruitment, payroll processing, etc.

- Finance

- Sales

- Marketing

- Logistics & Transportation

- Inventory management, and more!

So we see that manufacturing is not a stand-alone function but requires an interplay of different functions. In the pre-automation era, the processes were slow and prone to human errors. Besides, they required a large workforce to accomplish various tasks.

How Automation can be a game-changer in Manufacturing?

In a customer-centric market where “Customer is the King”, the focus of a manufacturing business is providing the customer with what they want, how they want, and where they want it. And, automation is the key to fulfilling all these demands of the customer. Automation streamlines various manufacturing functions for better outcomes.

Optimizing manufacturing functions reduces time to market, enhances the quality of products, reduces wastage, and boosts productivity.

Some of the technologies that come to the forefront to enhance customer experience and optimize manufacturing include:

The Cloud

The Cloud has facilitated seamless collaboration between various stakeholders. It offers a single point of truth for the seamless exchange of data. It has enabled various entities to interact from any location. The consequence of this has been quick decision-making and efficient workflows which are vital in reducing time to market.

RPA

RPA bots can perform various rule-based processes without human intervention. The benefits of using RPA include improved speed and accuracy. RPA relieves humans from tedious tasks so that they can perform high-skill jobs. Administrative tasks like manual data entry, documentation, pay-to-procure, invoice processing, etc., are the ideal candidates for RPA. Repetitive manufacturing processes can also be automated with RPA. Therefore, RPA enhances the efficacy of different administrative and non-administrative processes. This implies that the manufacturing cycle will be completed in a quick time with fewer errors providing better outcomes.

AI

The abilities of RPA can be greatly enhanced by making automation intelligent. Integrating AI or hyper automating various processes/workflows can boost the growth of the business.

Some areas where AI has a role to play include:

Forecasting

Manufacturing runs the risk of excessive or inadequate production. The quantity of products to be manufactured depends on the demand forecasts. Accurate demand forecasting has been a lacuna in legacy systems. AI overcomes this shortcoming. AI can collect large volumes of data and analyze it to make accurate forecasts. Accurate forecasting helps optimize multiple functions like procurement, inventory management, production planning, and more. Optimization of different functions reduces wastage and greatly minimizes the cost of production.

Product Design:

In a dynamic market, keeping pace with the changing customer demands is an uphill task. AI can be leveraged to analyze data for a better understanding of customer demands. Product design can be tailored to customer demands based on the insights provided by AI.

Marketing:

The primary objective of any manufacturing unit is to provide its customers with a great experience. Creating a quality product is the first step towards delighting your customers. However, marketing is a critical function that provides visibility to your brand and products. Marketing functions include attracting, converting, and retaining customers. AI has the power to enhance the marketing efforts of a business. ML, a subset of Ai is a self-learning technology. It studies data patterns to understand customer behavior and provides accurate insights to the marketing team. The data-backed marketing strategies are more effective and provide better outcomes.

Preventive Maintenance

Maintaining the machinery and equipment of a manufacturing unit is a vital function because any breakdown can prove to be very costly and result in losses. ML technology can identify anomalies and provide alerts to take timely action. Preventive maintenance ensures that various processes function seamlessly and there is no loss of work hours.

Besides these, AI can enhance various other functions like warehousing, logistics management, and more. AI chatbots enhance customer service. Data analytics and predictive capabilities of AI offer several benefits to a manufacturing unit.

AI works with RPA to hyper automate workflows. RPA automates routine processes but its capacity is limited because it works only with structured data. AI overcomes this shortcoming as it can harness unstructured data as well. Hyper automation greatly enhances the capacity of RPA.

IoT

IoT is another technology that has an important role to play in the manufacturing sector. IoT sensors can provide vital inputs to AI bots. AI leverages this data for better decision-making. One example of IoT in manufacturing is the presence of IoT devices on transportation units that help keep track of the inventory.

Digital Twin

A digital twin is a virtual model that simulates the life cycle of a physical object. It sends real-time data to monitor the behavior of equipment and operations. Digital twin technology has become a popular tool to optimize manufacturing.

AI and IoT work together to create a digital twin that boosts performance, accelerates production, facilitates remote monitoring, and more. A digital twin can be used throughout the entire manufacturing cycle. The digital twin picks up real-time data from IoT sensors and enables you to track performance, identify faults, and make better decisions about the manufacturing lifecycle and maintenance.

Procuring an automation tool without comparing it with others and integrating it into your manufacturing business will hardly help you achieve your goals! It is important to understand that several vendors are offering a myriad of automation tools but not every tool is right for your business!

Before you invest in automation, it is necessary to do some groundwork.

- Since automation is expensive, it is recommended that you decide the amount you wish to invest in it.

- It is a good idea to do a cost-benefit analysis to assess whether an investment in automation will justify its costs. While conducting a cost-benefit analysis, make sure that you consider the future demands of your business. This is because the benefits of automation are usually experienced over the long-term. Besides, automation helps your business scale seamlessly.

- You need to ascertain to what extent you want to automate your business, whether it is specific processes or enterprise-level automation.

- You will need to identify the processes that you want to automate.

- Determine what processes can be streamlined with RPA and where you require Hyper automation.

- Check if the automation tool can be integrated with your existing systems.

If all the above-mentioned factors overwhelm you, you can consult the experts at Auxiliobits. Our professional team has several years of experience in providing automation solutions to manufacturing businesses globally. We provide businesses with customized automation solutions for their business.

Call Us Now for the Best Automation Tools for your Business!

Watch this space to know more about what is happening in the world of automation!