Key Takeaways

- Autonomous AI agents enable real-time decision-making in manufacturing, helping reduce downtime and improve adaptability without the need for constant human oversight.

- These agents are designed with core characteristics like autonomy, situational awareness, goal orientation, and learning ability, making them highly efficient in complex production environments.

- A layered architecture— from data acquisition to decision-making and execution—is essential for effectively deploying AI agents in manufacturing control systems.

- Designing for operational intelligence involves building modular, edge-compatible, adaptive, and domain-specific agents that remain effective and responsive.

- A strong validation framework, including simulations, sandboxing, real-time monitoring, and retraining pipelines, is key to maintaining the reliability and safety of AI agents in real-world scenarios.

Manufacturing is one sector with constant requirements for suitable systems that lead to accurate control, reduce downtime, and adapt quickly. You might be curious to find out what drives these requirements. They are driven by customer demands, the rising complexity of production procedures, and unpredictable supply chains. Conventional manufacturing control systems do not have the skills and expertise to manage such requirements. One primary reason behind this is they follow guidelines set in advance. Hence, to overcome this problem, most manufacturing companies are exploring using autonomous AI agents. These are software programs that make swift decisions without relying on anyone else.

Autonomous AI agents do not depend on humans and can perform tasks, including monitoring machines, tracking performance, and responding to unwanted events. For example, if a machine stops functioning due to an issue, an AI agent will identify the problem and recommend a solution. This helps reduce downtime and ensures that nothing is hampered. AI agents work together, coordinate their actions, and share details. Henceforth, many parts of the manufacturing procedure sync, even though the environments may differ.

Also read: Autonomous Agents for Finance Teams: From Reconciliation to Reporting

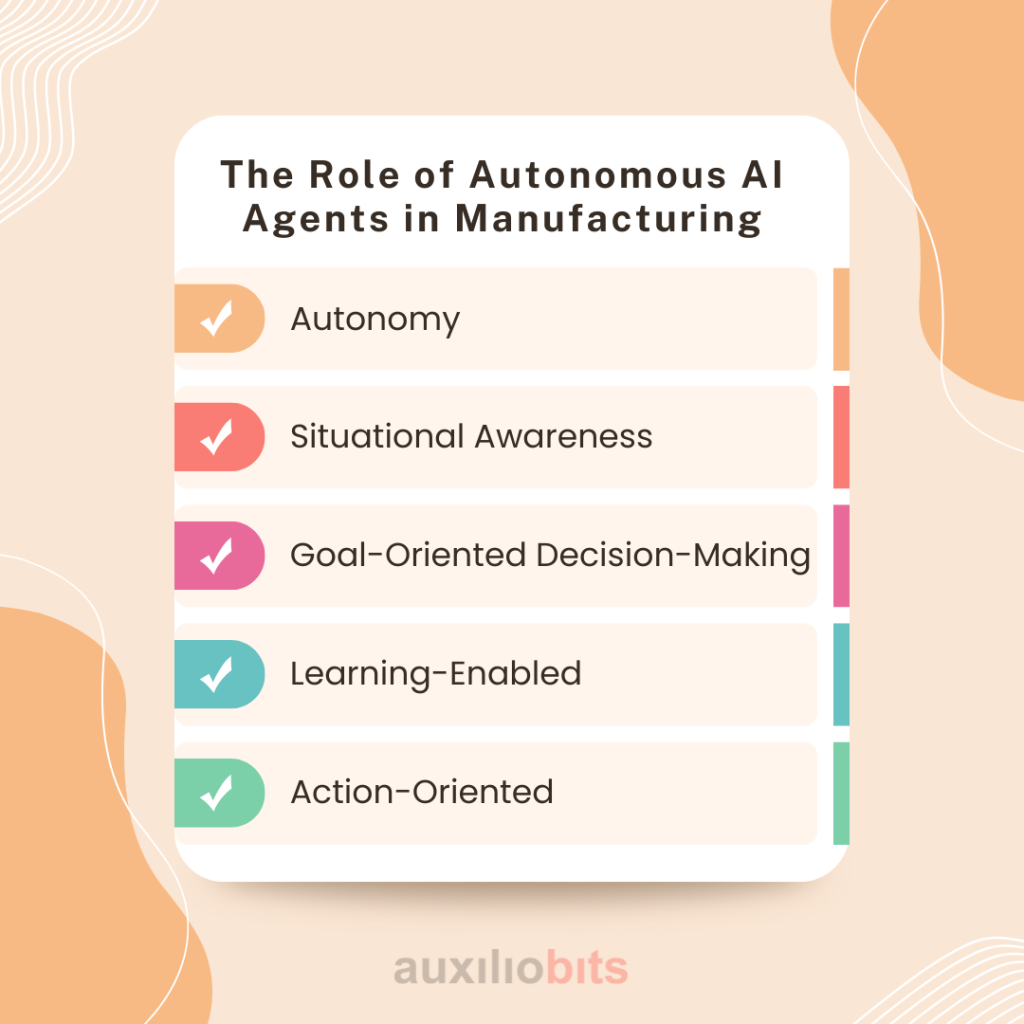

The Role of Autonomous AI Agents in Manufacturing

Autonomous AI agents are independent systems that function without any human direction. They are more aligned and efficient with company goals. There are several key characteristics of autonomous AI agents. We have listed them below:

1. Autonomy

Autonomous AI bots are incredibly proud of their capacity to carry out tasks effectively. After learning about the company’s requirements, they start to make decisions. This is one of the most notable benefits that businesses have access to. Companies also reduce the requirement for frequent human involvement when AI agents can handle operations independently. The agents also verify that company procedures are carried out successfully while considering environmental changes.

2. Situational Awareness

AI agents continuously collect and analyze data from various sources, including machine sensors, production logs, and external signals, such as supply chain updates. This real-time monitoring allows manufacturers to identify the present state of operations and determine when adjustments are needed.

3. Goal-Oriented Decision-Making

Each agent is programmed to pursue specific objectives, such as maximizing output, minimizing waste, or reducing energy consumption. They use available data to evaluate options and choose the actions that best support these goals.

4. Learning-Enabled

Over time, AI agents can improve their decision-making through learning techniques. They may use supervised learning (based on historical data), reinforcement learning (learning from actions’ outcomes), or unsupervised learning (identifying patterns in data). This allows them to refine their strategies and become more effective.

5. Action-Oriented

Beyond analysis, these agents also take action. They can send commands to machinery, adjust settings, or update software systems in real time, ensuring that decisions are followed through in the physical environment.

Overall, autonomous AI agents represent a significant advancement in manufacturing technology, bringing greater adaptability, efficiency, and intelligence to production systems.

Architectural Blueprint for Agent Deployment

Deploying autonomous agents in manufacturing control systems requires a layered architecture that bridges data acquisition, decision-making, and control execution. A well-designed system typically includes the following layers:

1. Data Acquisition Layer

This layer collects real-time data using sensors, programmable logic controllers (PLCs), SCADA systems, and edge devices. Key protocols include OPC UA, MQTT, Modbus, and Ethernet/IP. Ensuring high-frequency, low-latency data streams is critical.

2. Perception and Modeling Layer

Here, raw data is cleaned, structured, and used to form a contextual understanding of the production environment. This layer often implements digital twins of equipment or processes to provide virtual representations for simulation and prediction.

3. Decision-Making Layer

The core of the autonomous agent resides here. The agent evaluates the current state and determines the best action using machine learning algorithms such as deep reinforcement learning, Markov decision processes, or rule-based AI.

4. Execution Layer

Decisions made by the agent are converted into control actions. These could involve adjusting machine parameters, changing process sequences, or initiating maintenance routines. Integration with PLCs or industrial controllers ensures seamless actuation.

5. Coordination Layer (Optional)

In environments with multiple agents (e.g., a smart factory), a coordination layer manages inter-agent communication, load balancing, and conflict resolution. Multi-agent systems (MAS) frameworks and message brokers like Apache Kafka or ROS2 facilitate distributed decision-making.

Designing for Operational Intelligence

Developing autonomous AI agents for manufacturing involves more than integrating advanced algorithms. It requires a strong foundation in operational intelligence—an approach that combines real-time data processing with AI-driven insights to support informed, timely, and automated decision-making. The goal is to create systems that not only understand what is happening on the factory floor but can also take action to improve performance, respond to disruptions, and align with business goals.

To design agents that can deliver this level of intelligence, developers must follow several core principles. These principles ensure that agents are technically sound but also practical and effective within a manufacturing facility’s complex and fast-paced environment.

1. Modularity

One of the key principles in agent design is modularity. Each agent should be built as a self-contained unit that can perform specific tasks independently while also being able to communicate and collaborate with other agents or systems. This modular approach allows for easier scaling, maintenance, and updates. It also supports system flexibility—new agents can be added or removed without disrupting the entire system, which is essential for adapting to changes in production processes or business needs

2. Edge Compatibility

In manufacturing, timely decision-making is critical. Agents must often respond in real time to events such as equipment malfunctions, safety hazards, or production delays. To minimize latency, AI agents should be designed to process data at the edge—near the machines and sensors generating the data—rather than relying on centralized cloud-based systems. Edge computing allows for faster data analysis and action, allowing agents to deliver quicker, context-aware responses.

3. Domain-Specific Modeling

Manufacturing involves many processes, from robotics and assembly lines to material handling and thermal operations. A one-size-fits-all model is not effective in this environment. Agents should use models that are specifically designed for the domain they operate in. For example, a robotic agent may require kinematic modeling to handle movement and positioning, while an agent monitoring a furnace may need thermodynamic models to manage heat levels. Domain-specific modeling ensures accurate decision-making and greater operational efficiency.

4. Adaptivity

Manufacturing conditions can change rapidly due to machine wear, supply chain issues, or changing production goals. Therefore, agents must be designed to adapt dynamically. They should continuously learn from new data and adjust their strategies or parameters accordingly. This adaptability makes them more resilient and capable of long-term optimization.

By applying these design principles, manufacturers can build autonomous agents that enhance operational intelligence and deliver meaningful improvements in performance and responsiveness.

Validation and Assurance Frameworks

As autonomous AI agents become more integrated into manufacturing control systems, ensuring their reliability, safety, and performance becomes critically important. Unlike traditional systems, which follow fixed rules and are easier to predict, AI-driven agents operate using adaptive models and data-driven decision-making. This introduces new challenges in validation and assurance, requiring a comprehensive framework to verify that agents behave safely and effectively under real-world conditions.

A strong validation and assurance framework is essential to building trust in autonomous systems, avoiding production disruptions, and meeting compliance and safety standards. Several key components form the foundation of such a framework. We have listed them below:

1. Simulation-Based Stress Testing

Before deploying AI agents into live manufacturing environments, testing them under simulated conditions is essential. Simulation-based stress testing allows developers to expose agents to various scenarios—including edge cases, failures, and unexpected inputs—without risking real-world assets. These simulations help identify weaknesses in the agent’s logic, measure its decision-making under pressure, and ensure it can respond appropriately to abnormal events.

2. Digital Sandboxing for Agent Behavior

Digital sandboxing refers to creating a controlled virtual environment where agents can operate independently and be observed without affecting the physical production process. This technique is beneficial for testing new agents, updates, or configuration changes. Within the sandbox, developers can monitor behavior, analyze decision paths, and verify compliance with operational rules. It serves as a safe testing ground before full-scale deployment.

3. Real-Time Monitoring and Overrides

Once deployed, AI agents must be continuously monitored in real-time to detect anomalies, unexpected actions, or system failures. Monitoring tools can track key performance indicators (KPIs), system logs, and sensor data to ensure the agent functions as intended. In addition, manual or automated override mechanisms must be in place. These allow operators to intervene and take control if an agent behaves unpredictably or conditions require human judgment.

4. Continuous Model Retraining Pipelines

The manufacturing environment is dynamic—conditions change, machines age, and new data is constantly generated. AI models powering autonomous agents must be regularly updated to maintain accuracy and performance. Continuous retraining pipelines allow models to learn from new data while maintaining operational integrity. Retraining processes should include validation checks to prevent performance degradation or the introduction of errors.

Together, these validation and assurance practices create a robust framework that supports the safe, effective, and responsible deployment of AI-driven agents in manufacturing settings.

Conclusion

Autonomous AI agents are transforming manufacturing by bringing intelligence to the control layer. Their capacity to sense, decide, and act at scale can drive significant gains in quality, efficiency, and agility. The road to adoption requires careful planning, robust architecture, and a continuous feedback loop to ensure reliability and trustworthiness.